Nylon is a synthetic polymer made up of polyamides (polymers connected together by amide bonds). When it comes to 3D printing, nylon is frequently referred to as an “advanced” material because it necessitates considerable expertise and specific equipment. Powder or filament can be used to 3D print nylon. Here is what you need to know about nylon 3D printing.

Physical and Chemical Properties

Despite being a little difficult to 3D print, the material’s qualities make the effort worthwhile. Nylon is a popular material for industrial 3D printing because it is robust, resilient, and resistant to abrasion. It can provide decent flexibility while remaining robust if printed thin enough. Because of its low coefficient of friction, nylon is ideal for constructing functional moving parts. As a result, nylon is frequently utilized to create working prototypes, living hinges, gears, and other end-use components. Two more features of nylon are necessary to fully comprehend nylon 3D printing. It’s hygroscopic, which means it loves to absorb moisture, and it has a high melting point.

FDM

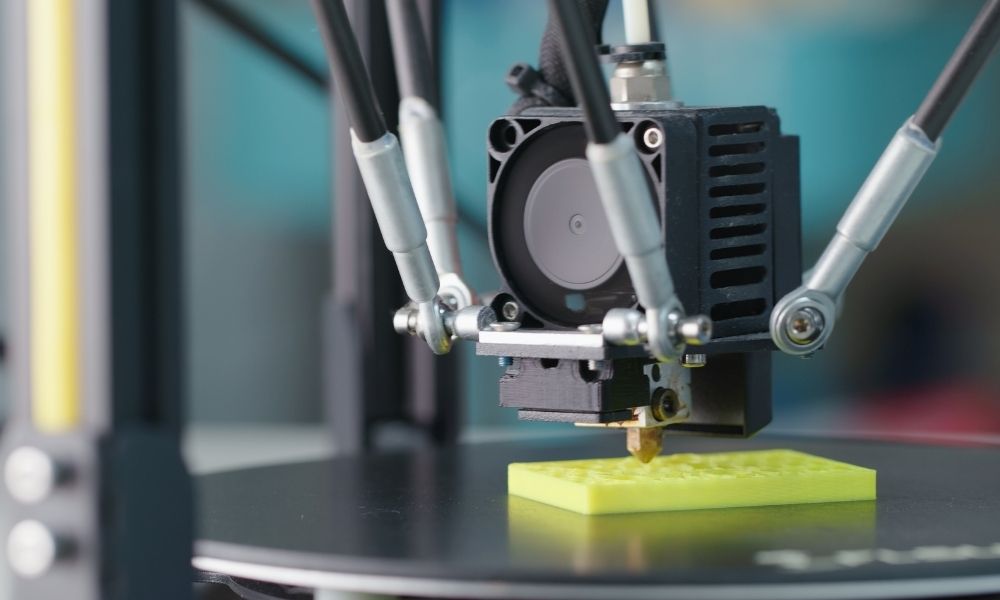

Because MJF and SLS printers, as well as the powders they employ, are not inexpensive, 3D printing with nylon can be pricey to start into. Fortunately, using an FDM printer and special nylon filament, it is possible to 3D print nylon. Filaments are melted and then extruded through a nozzle onto the build platform in stages until the part is complete in FDM 3D printers. While 3D printing nylon on an FDM printer is far more accessible than SLS or MJF, the quality of FDM-printed nylon parts is not as good.

Storage and Printing

Moisture absorption that is too high can cause the filament to degrade. When filament degrades, it loses its qualities, and nylon filament can degrade in just a few hours. Proper storage is essential to avoid such a situation. When the filament is not in use, a basic plastic airtight container is an excellent solution, but what about when printing? The optimum solution is a humidity-controlled storage facility that also allows the filament to enter the extruder. If it’s too late and your spool has already absorbed too much moisture, carefully drying your filament may be able to rescue it.

We hope we have covered all your questions in our overview on nylon 3D printing. While it can be hard to determine the right modeling method for your print, making the right choice will result in a world of difference. Look here today for help before you begin your next nylon print!